Title: SYNTACTIC POLYURETHANE ELASTOMERS FOR USE IN SUBSEA PIPELINE INSULATION

Number/Link: WO2015065769 WO2015065770 WO2015065771 WO2015065772

Applicant/Assignee: Dow

Publication date: 7-05-2015

“Gist”: Zn/Zr catalyzed syntactic elastomers for subsea pipeline insulation

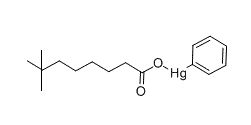

Why it is interesting: Conventional polyurethane rigid foams cannot be used for the insulation of subsea pipelines because the foams would collapse under the pressure and they are too brittle to be bent. For these reasons syntactic elastomers can be a better choice for this application. Syntactic polyurethane elastomers consist of a solid PU matrix containing up to 50% (wt/wt) of hollow glass microspheres. The catalyst of choice to produce these materials is phenylmercury neodecanoate. However because of regulatory pressure other catalyst systems are now being used. The gist of these four patent applications appears to be the use of a mixture of a zinc carboxylate with a small amount of zirconium carboxylate as a replacement for the organomercury catalyst, but this is not the main claim (probably because of non-patentability). Instead the WO..69 case is about the use of polymer polyols in these systems, the WO..70 case is about the use of low unsat polyols, WO..71 is about a special type of morphology and WO..72 about the use of prepolymers.