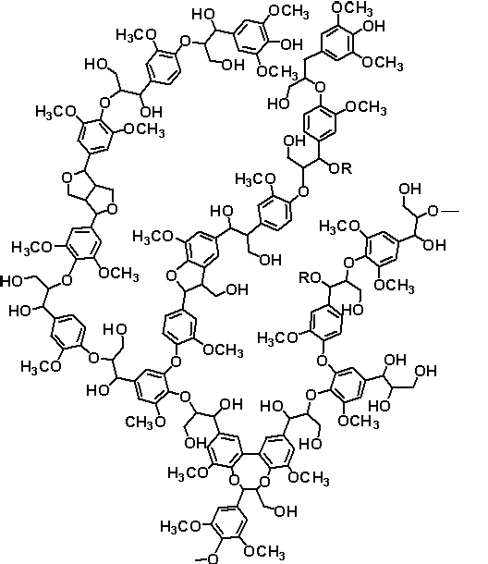

Title: COMPOSITIONS OF PHENOLIC BIOPOLYMERS

Number/Link:WO2015/055662

Applicant/Assignee: Solvay

Publication date: 23-04-2015

“Gist”: Lignin is emulsified in a halogenated polyol and then used to prepare rigid foams.

Why it is interesting: This case is about yet another attempt to incorporate lignin into polyurethane materials. In this invention lignin is dispersed in a halogenated polyol using a suitable milling process. The polyol is preferably a brominated ‘rigid’ polyether. The dispersed lignin (pref.) has a (d90) mean particle size of less than 100μm and is used in an amount of up to about 50% on the brominated polyether. The lignin dispersion can then be used together with other polyols in rigid foam formulations. The resulting foams should have improved flammability properties and the lignin is said to have no negative effect on thermal insulation properties.