Title: CARDANOL MODIFIED EPOXY POLYOL

Number/Link: WO2015/077944 WO2015/077945 WO2015/078178

Applicant/Assignee: Dow

Publication date: 4-06-2015

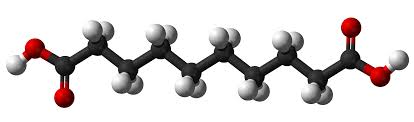

“Gist”: Polyols are prepared by reacting an epoxy resin with cashew nutshell liquid.

Why it is interesting: Cardanol is the main component of cashew nutshell liquid which is a by-product of cashew nut processing. It is a “surfactant-like” phenolic compound which, when reacted with a polyepoxide, will result in a polyol with sec-OH groups. When used in polyurethane formulations these polyols will (unsurprisingly) be slow-reacting, highly hydrophobic and show compatibilizing properties vs apolar compounds. Dow have therefore filed three patent applications on PU systems containing these polyols: one on slowly-reacting PU systems for filament winding, one on highly hydrophobic PU elastomers and one on asphalt-PU compositions.

These are interesting polyols but they could be hard to process in my opinion.