Title: Process for the preparation of cold-hardening flexible polyurethane foams having excellent deadening properties.

Number/Link: EP0331941

Applicant/Assignee: Bayer

Publication date: 13-09-1989

“Gist”: Highly damping flexible foams are made using a mixture of three specific polyols.

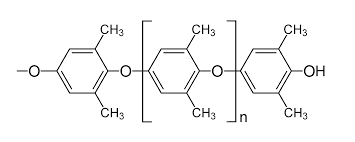

Why it is interesting: “Visco” or “memory” foams are currently known especially for their use in matresses and pillows. Originally however these “dead” foams were developed as vibration damping materials for acoustic applications. The invention is based on the use of three specific polyols: (a) a ‘normal’ PO/EO-tipped triol with a hydroxyl value of about 28, (b) a ‘rigid’ all-PO triol with OHv of about 350 and (c) a ‘high EO’ triol with an EO content of about 75% and OHv of 36. The polyols are used in a ratio of about 25:15:60 (a:b:c) together with either TDI or MDI. Because the polyols are relatively immiscible the resulting foams have a soft-phase glass transition which is ‘smeared’ out over a temperature range controlled by polyol (a) at the low end and by (c) at the high end – ranging e.g. from -30°C to +10°C. This wide glass transition in turn results in a very wide damping frequency range. A very clever idea that has been copied many times.