Title: KOMBINATIONSSCHAUM

Number/Link: WO2014/023794 (German)

Applicant/Assignee: BASF

Publication date: 13-02-2014

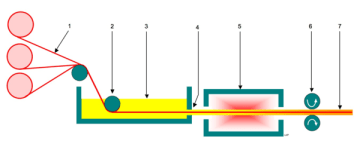

“Gist”: Foamed TPU particles are embedded in a foamed elastomer of the same chemical composition to improve mechanical properties.

Why it is interesting: Foamed, closed-cell TPU particles are incorporated in a foamed, open-cell PU matrix which has a higher density and is produced from essentially the same chemicals, resulting in perfect compatibility and adhesion between the two components. In the examples 30-40 % (w/w) of expanded TPU particles with a bulk density (“Shüttdichte”) of 89 kg/m³ are incorporated in an elastomer with a density of 200-300 kg/m³. Size of the TPU particles is not given but the preferred size range is 1mm to 2 cm.