Patent Title: NON-SOFTENING RESILIENT THERMOPLASTIC POLYURETHANES

Number/Link: WO2016/054320

Applicant/Assignee: Lubrizol

Publication date: 7-04-1016

“Gist”: TPU from a blend of HDI and H12MDI has improved creep and wet modulus

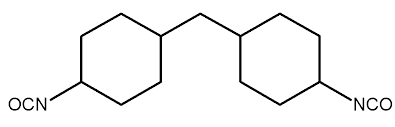

Why it is interesting: Polymeric materials used for in vivo medical applications like catheters, need to be hydrolytically stable and retain physical properties like stiffness, resilience, flexibility etc. in wet conditions. It is known that conventional TPUs based on aromatic or cyclo-aliphatic isocyanates tend to show some softening in aqueous environments. For this reason copolyamides (COPAs) and polyether-block-polyamides (PEBAs) are often preferred over TPU for use in medical devices. According to this invention, TPUs that can replace COPA and PEBA in medical applications can be produced using a blend of 1,6-hexanediisocyanate (HDA) and H12MDI. In the examples polyether TPUs, prepared from 2000MW polytetramethyleneether diol, butanediol and a 19:1 HDI:H12MDI isocyanate blend at harblock contents ranging from 15 to 50%, convincingly show improved creep properties and wet modulus when compared to conventional TPU and a commercial PEBA material.