Title: CAST-MOLDED HEAT-CURABLE POLYURETHANE ELASTOMER

Number/Link: WO2015/159875 (Japanese)

Applicant/Assignee: UBE

Publication date: 22-10-2015

“Gist”: 1-10% of a polyrotaxane is incorporated in a hot cast PU elastomer system

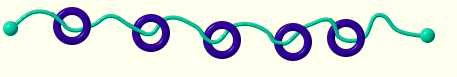

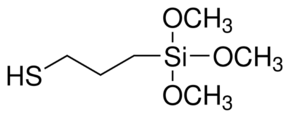

Why it is interesting: Polyrotaxanes are molecular systems consisting of a linear polymer which is “threated” through a number of ring-shaped molecules. The rings are prevented from ‘sliding off’ by blocking-molecules at both ends of the “thread”. In this invention polyrotaxanes based on a polycaprolactone thread and cyclodextrin rings (pref.) are incorporated in hot cast elastomer systems in amounts of 1-10% (w/w). Because cyclodextrin rings contain hydroxyl groups they react with the isocyanate incorporating the polyrotaxane in the PU polymer. The systems are said to have processing and property advantages for specific elastomer applications, in this case printer rollers – if I understand the machine translation correctly.