Title: RIGID FOAM AND ASSOCIATED ARTICLE AND METHOD

Number/Link: WO2015/012989

Applicant/Assignee: SABIC

Publication date: 29-01-2015

“Gist”: Rigid polyurethane foams containing polyphenylene ether particles

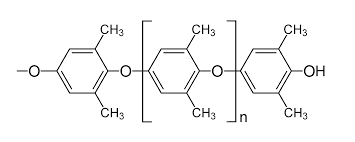

Why it is interesting: This invention is about rigid PU or PIR (polyisocyanurate) foams containing up to 25% w/w on the total composition of poly(2,6-dimethyl-1,4-phenylenether) particles. The particles have a mean particle size of about 6 µm and are prepared by jet milling a commercial grade of PPE powder. The resulting foams are said to have reduced flammability and water absorption. This is the second patent application that SABIC files on PPE-PU hybrids or combinations. An interesting development but it is hard to believe that these ideas are practical and economical.