Title: POLYURETHANE COMPOSITES COMPRISING NANOCRYSTALLINE CELLULOSE AND METHOD FOR IMPROVING PROPERTIES OF POLYURETHANES THEREOF

Number/Link: WO2014/190428

Applicant/Assignee: Celluforce

Publication date: 4-12-2014

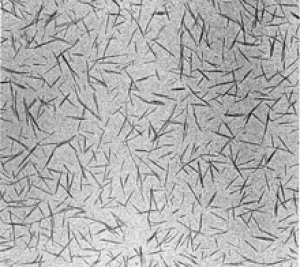

“Gist”: A small amount of nanocrystalline cellulose improves mechanical properties of polyurethanes

Why it is interesting: Nanocrystalline cellulose or NCC is cellulose in the form of nano-scale crystals or fibrils produced from woodpulp. A few years ago NCC was hailed as a disruptive new “wonder material” with the potential to replace metal and make existing plastics obsolete. The current patent application claims the use of NCC in polyurethanes, added in amounts of (preferably) less than 1% to either the polyol or isocyanate stream. Both tensile and elongation values of the PU are said to improve. While this may well be true and NCC is no doubt an interesting material this case is most probably not patentable. Too little, too late.