Patent Title: NON-ISOCYANATE POLYURETHANES AND METHODS OF MAKING AND USING THE SAME

Number/Link: WO 2017/ 030880

Applicant/Assignee: ELEVANCE RENEWABLE SCIENCES

Publication date: 23-feb-2017

“Gist”: Telechelic cyclocarbonate-alkylesters are reacted with diamines in the melt

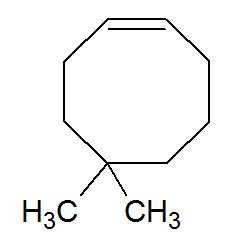

Why it is interesting: According to this invention (ω-) unsaturated alkylesters can be converted to mono-cyclocarbonate alkylesters and then reacted with diamines to prepare thermoplastic poly(amide-hydroxyurethanes) (PAHU). For example methyl-9-decenoate was first epoxidized and then reacted with CO2 to produce 9,10-cyclic carbonate-methyl decanoate. After separation and washing the cyclocarbonate was reacted – in the melt- with a mixture of dodecane diamine and a PTMO diamine (Jeffamine THF-100). It is said that the unsaturated alkylesters can be prepared from natural oils using (cross- or self-) metathesis followed (or preceded) by transesterifaction with alkanols.