Patent Title: BIO-BASED DIISOCYANATE AND CHAIN EXTENDERS IN CRYSTALLINE SEGMENTED THERMOPLASTIC POLYESTER URETHANES

Number/Link: WO2016041076

Applicant/Assignee: Trent University

Publication date: 24-03-2016

“Gist”: TPU with highly crystalline hard segment is based on 1,7 heptamethylenediisocyanate

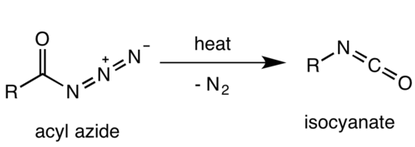

Why it is interesting: According to this application, polyester TPUs with crystalline hard segments can be produced using 1,7-heptamethylenediisocyanate. The HPMDI is reacted with a 2000MW poly(ethyleneadipate) diol and a short chain diol as chain extender. The TPUs show a high hard-segment crystallinity, resulting in improved phase separation and in a (semi-)crystalline softphase which has a significant reinforcement effect. The TPUs are thermally stable up to 250°C and show a toughness and strength comparable to conventional TPUs. HPMDI can reportedly be made from natural oils using the Curtius rearrangement – but no reference is given.