Title: ISOCYANATE PREPOLYMER COMPOSITION AND CROSSLINKED POLYURETHANE PREPARED THEREFROM

Number/Link: WO2015/007731

Applicant/Assignee: BASF

Publication date: 22-01-2015

“Gist”: Melt spinning a TPU – prepolymer blend.

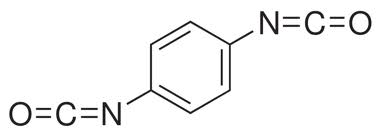

Why it is interesting: Crosslinked polyurethane fibers are produced by melt-spinning a thermoplastic polyurethane which is melt-blended with a specific isocyanate prepolymer composition. The prepolymer composition is a mixture of a polymeric MDI and the reaction product of a polyester polyol and an excess of 4.4′-MDI. The polyester polyol is prepared from adipic acid together with 2-methyl-1,3-propanediol (MPdiol) and/or trimethylolpropane. The prepolymer composition is characterized by its low viscosity (probably due to the use of the branched polyester). The crosslinked fibers show an improved tensile set and temperature resistance.