Title: Foam Composition and its Uses Thereof

Number/Link: US2014/079940

Applicant/Assignee: MAS RES AND INNOVATION PVT

Publication date: 20-03-2014 (priority PCT)

“Gist”: Use of 4 catalysts: 2 ‘normal’ and 2 ‘delayed action’ are used to formulate pour-in-place foams that resist fabric penetration.

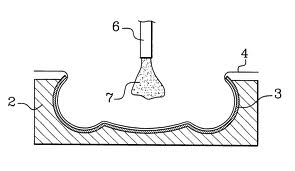

Why it is interesting: “Pour in place” or “in situ” foaming is a technique where a flexible foam-forming mixture is poured directly onto fabric to (typically) produce car seats. The fabrics used are often laminated with a thermoplastic film or a layer of polyester PU foam to prevent penetration of the foaming mixtures. These liners however impair breathability and therefore comfort. The current invention should allow use of liner-free fabrics without strike through. Four different catalysts are used: a normal gelling catalyst, a normal blowing catalyst a delayed action gelling catalyst and a delayed action blowing catalyst. The delayed action catalysts are conventional amine catalysts reacted with a suitable acid like lactic acid and become active at a temperature of around 50°C. When poured on a fabric-lined and heated mould, a flexible foam mixture formulated with these catalysts should gel imediately and not penetrate the fabric.