Patent Title: ALIPHATIC THERMOPLASTIC POLYURETHANES, PRODUCTION AND USE THEREOF

Number/Link: WO2018/192936 (German)

Applicant/Assignee: Covestro

Publication date: 25 October 2018

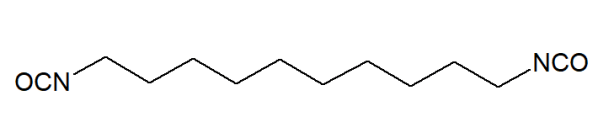

“Gist”: TPU based on 1,10-decanediisocyanate shows reduced blooming

Why it is interesting: Aliphatic thermoplastic polyurethanes, based on hexanediisocyanate (HDI) can show “blooming” i.e. the formation of a white precipitate on the surface of the material. It is believed that this is caused by the formation of cyclic oligourethanes migrating to- and forming crystals on the surface. According to this invention, this blooming behaviour can be prevented by using long-chain aliphatic diisocyanates like 1,10-diisocyanatodecane or 1,12-diisocyanatododecane instead of HDI.

1,10-diisocyanatohexane (DDI)