Title: URETHANE FOAM RUBBER AND COMPOSITION FOR FORMING URETHANE FOAM RUBBER

Number/Link: US20150105485

Applicant/Assignee: Yamaha

Publication date: 16-04-2015

“Gist”: Use of carbodiimide-MDI to make soft high resilience elastomers

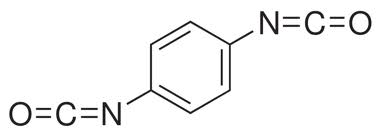

Why it is interesting: According to this patent application, soft, high-resilient PU elastomers with a density higher than 300 kg/m³ can be prepared from a diisocyanate, a polyether polyol with a molecular weight of about 1000 to 4000 together with some polymeric MDI. The invention being, that the diisocyanate needs to have an “atom number minimum bond path” between the two NCO groups of at least 11. Examples of such diisocyanates would be α,ω-undecane- (or dodecane- or tridecane- etc.) diisocyanates, propylene-1,3-di(1,4-cyclohexylene diisocyanate) but also carbodiimide modified MDI which is preferred. Examples are given of 440 kg/m³ elastomers with a ball rebound of 81 and an Asker C hardness of 44 at temperatures ranging from -20°C to 50°C, based on a polyTHF diol with a MW of 2000 and a carbodiimide modified MDI. No other isocyanates are used in the examples, so it appears to me that the “atom number minimum bond path” is just an attempt to make this case new and patentable. Not very convincing. I would like to see an example with tridecanediisocyanate.