Patent Title: AMIDE BASED COATING

Number/Link: WO2017/213855

Applicant/Assignee: Dow

Publication date: 14 December 2017

“Gist”: Proppant particles are coated with polyamide based on isocyanate and carboxylic acids

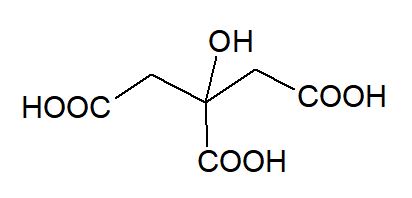

Why it is interesting: Proppant particles are used in the hydraulic fracturing process to force open rock fissures to extract gas and oil – as discussed before in this blog. According to this invention the proppant particles are coated with a reacting mixture of a polyisocyanate (e.g. polymeric MDI) and polycarboxilic acids (e.g. a blend of citric acid and an acid-terminated polyether triol). Under the high pressure and temperature of the fracture, the coating will bond the proppant particles together, thus preventing flow-back of the proppant and the blocking of the well. The coating can contain additives to capture heavy metals like radium and sulfides like hydrogensulfide to reduce contamination of the fracture fluid.

Citric acid