Title: ADDITIVE FOR ADJUSTING THE GLASS TRANSITION TEMPERATURE OF VISCO-ELASTIC POLYURETHANE SOFT FOAMS

Number/Link: WO2013/131710

Applicant/Assignee: Evonik

Publication date: 12-09-2013 (German)

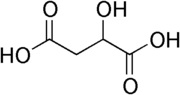

“Gist”: Use of the di-salt of malic acid to fine-tune the Tg of visco flex foams.

Why it is interesting: The comfort properties of viscoelastic (“memory”) foams are to a large extend controlled by the glass transition temperature of the softblock, which in turn is controlled by NCO index, softblock molecular weight, crosslink density etc. Changing these parameters can be complex however because other properties -like airflow- are affected as well. This invention teaches the surprising effect of the di-sodium-salt of malic acid (hydroxybutanedioic acid) on the Tg of these foams. Apparently a small amount of the compound has a large effect on the Tg and can therefore be used to adjust the Tg without affecting other properties to a large extend. E.g. about 0.1 php of the salt drops the Tg with 5.5°C, by comparison 0.1 php butanol lowers the Tg only by 0.3°C.