Title: PROCESS FOR THE MATERIAL UTILIZATION OF POLYURETHANES

Number/Link: WO2013/134801 (German)

Applicant/Assignee: Eurofoam

Publication date: 19-09-2013

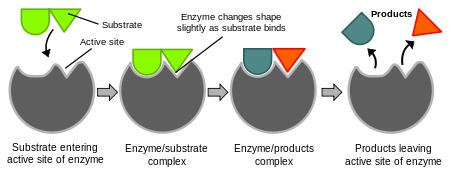

“Gist”: Use of specific enzymes to break down polyurethane into polyamines and its original (polyether)polyols

Why it is interesting: Chemical recycling of polyurethane by hydrolysis, glycolysis etc. is known but requires high temperatures and sometimes (when supercritical water is used) high pressures. This can lead to side reactions and the contamination of the recycled raw materials. Enzymatic recycling of polyurethanes is known as well but is mostly limited to polyester polyurethanes and esterase enzymes which break down the ester bonds. The current invention claims that the use of certain hydrolases of the EC3 class, especially arylacylamidase EC3.5.1.13 selectively breaks the urethane bond. (EC=enzyme comission number). The reaction can be carried out between 30 and 50°C and at a pH of 9.5 to 11. The resulting polyols and amines can be extracted using a polar solvent. While interesting the proposed process may not be very practical as the example shows that 5 days were needed to recycle a 5 gram sample of a model foam.