Patent Title: METHOD FOR MANUFACTURING A POLYURETHANE-MODIFIED FOAM, FOAM OBTAINED, AND USES

Number/Link: US2018/0030196

Applicant/Assignee: Soprema et al.

Publication date: 1 February 2018

“Gist”: Unsaturated natural oils are epoxidized and reacted with an excess of isocyanate in the presence of a blowing agent.

Why it is interesting: Conventionally natural oils are incorporated into polyurethanes by first converting them to polyols (“NOPs”) by hydroformylation or epoxidation and ring opening and then reacting the NOPs with isocyanates. According to this invention the natural oils (preferably extracted from microalgae) are epoxidized and then mixed and heated with a (e.g. 3:1) excess of isocyanate (e.g. polymeric MDI) in the presence of a blowing agent (e.g. isopentane). It is said that oxazolidone rings from the isocyanate-epoxy reaction will form at the same time as isocyanurate rings and homopolymerized epoxides. The foams are said to be useful for thermal insulation applications.

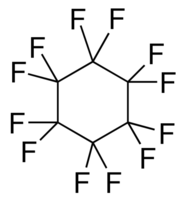

Formation of oxazolidone rings according to the invention