Title: HIGH RESILIENCY POLYURETHANE FOAMS MADE WITH HIGH FUNCTIONALITY, HIGH EQUIVALENT WEIGHT POLYOLS WITH MAINLY SECONDARY HYDROXYL GROUPS

Number/Link: WO2017/062150

Applicant/Assignee: Dow

Publication Date: 13 April 2017

“Gist”: Use of high functionality polyols increases the resilience of flex foams

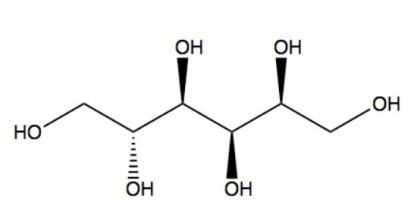

Why it is interesting: According to this invention the resilience of flexible PU foams can be increased by using, as part of the polyol composition, a random EO/PO polyether polyol which has an equivalent weight of at least 1500, a functionality of at least 5, a secondary hydroxyl group content of at least 70%, an unsaturation value of at most 0.01 meq/g and an EO content between 5 and 30%. In the examples, sorbitol initiated polyols are used in both MDI and TDI-based systems, resulting in ball rebound values of up to 60% at densities of about 30 kg/m³. As I have shown in the past (US5521226) the same (or arguably an even stronger) effect on resilience can be obtained with other high functionality polyols, indicating that the unsaturation value, primary OH content, EO content and equivalent weight are probably not relevant to the resilience increase.