Patent Title: TIME RELEASED DELIVERY OF FUNCTIONAL CHEMICALS

Number/Link: US2018/0127638

Applicant/Assignee: Covestro

Publication date: 10 May 2018

“Gist”: Functional chemicals are reacted with isocyanates for controlled release in fracking wells.

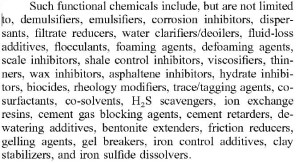

Why it is interesting: Hydraulic fracturing for oil and gas production is a complex process that requires a “fracking fluid” containing a proppant together with a host of chemicals like defoamers, demulsifiers, biocides etc. According to this application it is advantageous that these chemicals are released slowly over time during the complete lifecycle of the well. It is stated that this can be achieved by reacting the additives with mono- or polyfunctional isocyanates and (e.g.) incorporating these compounds into the proppant coating. The additives should have an active hydrogen able to react with isocyanate, or be modified to have such.

The text does not propose a mechanism for this controlled release and it is not clear why this should work. And -strangely- the “examples” section does not contain any examples.

Some fracking fluid additives.