Patent Title: AQUEOUS PEPTIDE-FUNCTIONALIZED POLYURETHANE DISPERSIONS

Number/Link: WO2016/135162

Applicant/Assignee: Henkel; Max-Panck Ges.

Publication date: 1-09-2016

“Gist”: A maleimide-capped prepolymer is reacted with the -SH groups in a peptide

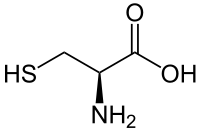

Why it is interesting: Polyurethane-protein hybrids are interesting novel materials which potentially have a number of unique properties unattainable with conventional synthetic polymers. In a previous case discussed in this blog an NCO-ended polyurethane prepolymer was reacted with a peptide in water to make a PU-peptide dispersion. This type of grafting, however, is not very specific because the isocyanate will react mostly with the free amino groups of lysine, which is usually ‘abundant’ in a typical peptide. According to this invention the grafting can be made very specific by first end-capping the NCO prepolymer with maleimide groups and dispersing in water. The dispersion is then reacted with a peptide solution at pH7. In these circumstances the maleimide will react selectively with the free thiol group of cysteine, of which usually very few are present in a typical peptide because most thiol groups are engaged in S-S disulfide bridges. Preferably a peptide consisting of 10-200 amino acids is used, with preferably only one free thiol group. By selective grafting the properties of the peptide can be conserved. The PU-peptide dispersions are claimed to be especially useful for metal adhesives.