Title: THERMOPLASTIC POLYURETHANE AND ASSOCIATED METHOD AND ARTICLE

Number/Link: WO2014/209934

Applicant/Assignee: Sabic

Publication date: 31-12-2014

“Gist”: Thermoplastic Polyurethanes based on polyphenylene ether diols

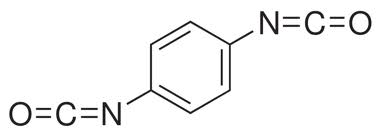

Why it is interesting: This invention relates to thermoplastic polyurethanes prepared from hydroxyl ended polyphenylene ethers (PPE) and diisocyanates. Optionally the PPE diols can be blended with ‘conventional’ polyether or polyester diols and chain extenders. The resulting TPUs are reported to have increased chemical resistance and hydrophobicity. In the examples copolymers of 2,6-dimethylphenol and 2,2-bis(3,5-dimethyl-4-hydroxyphenyl)propane with molecular weight between about 1000 and 3000 are reacted (in solvent)with MDI or TDI using DBTDL as a catalyst. The resulting thermoplastic materials had a Tg of about 160 to 170°C. While these could be interesting engineering thermoplastics, I guess they would be difficult to produce and difficult to process.