Title: MICHAEL ACCEPTOR-TERMINATED URETHANE-CONTAINING FUEL RESISTANT PREPOLYMERS AND COMPOSITIONS THEREOF

Number/Link: US2015/0252232

Applicant/Assignee: PRC-DeSoto

Publication date: 10-09-2015

“Gist”: A PU prepolymer is capped with Michael accepting groups and then cured with a dithiol

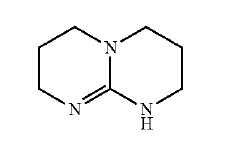

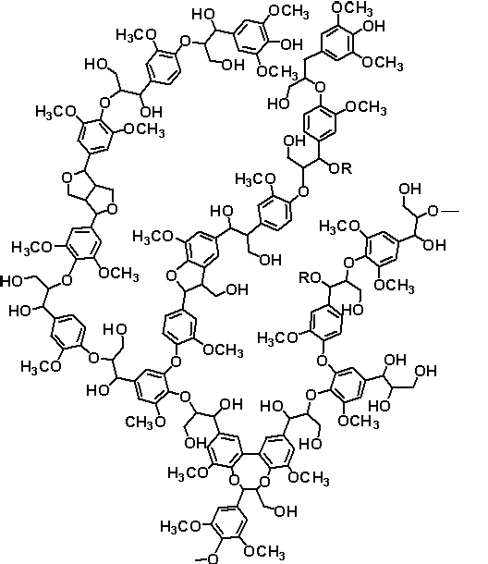

Why it is interesting: This invention is about sulphur containing PU sealants with properties acceptable for the aerospace industry. A bis(vinylsulfonyl)- terminated urethane-polythioether prepolymer is prepared according to the scheme below. The prepolymer can then be cured with a dithiol-ended polyether, catalysed by a tertiary amine. The compositions have an extended pot life and the curing rate can be controlled by using an encapsulated tert-amine as a controlled-release catalyst.